One of the best decisions I made when self-building my own house was to specify beam and block intermediate flooring.

In this article I thought I’d expand on the subject and explain in detail why this system is such a good choice, not just at ground floor level but also for upper storeys – at least where it’s practical for your scheme.

Oversite options

Once the footings are in, you’ve got a choice in terms of what you use as the platform (the oversite) on which your home will be built.

Years ago, the simplest solution was to fit timber joists covered in floorboards. But suspended timber structures can be draughty and noisy, so they won’t suit modern self-builds, where decent levels of insulation and airtightness are required.

The most straightforward option today would be a concrete slab laid on top of compacted hardcore. The latter would be covered with a layer of sand (known as binding) to protect against sharp edges, plus rigid foam insulation on a damp proof membrane.

While this is a common choice, the labour requirement is reasonably high – plus you’ll need to wait for the concrete to cure before work can continue.

New systems appear all the time. Fully-integrated insulated slabs are now a popular choice on high-spec eco homes, for example. Even more common, however, is the use of beam and block for the oversite – and potentially intermediate floors, too.

What is beam and block?

The system comprises a series of inverted T-beams made of pre-stressed concrete, which look remarkably similar to train rails in profile. These beams are cut to a specified length – determined by the construction drawings.

On site, they are laid perpendicular to the supporting blockwork walls that make up the inner leaf of the footings (at ground floor level). The rails rest on a damp proof course and have a 100mm bearing; in other words, they cover the whole width of that inner leaf of blockwork.

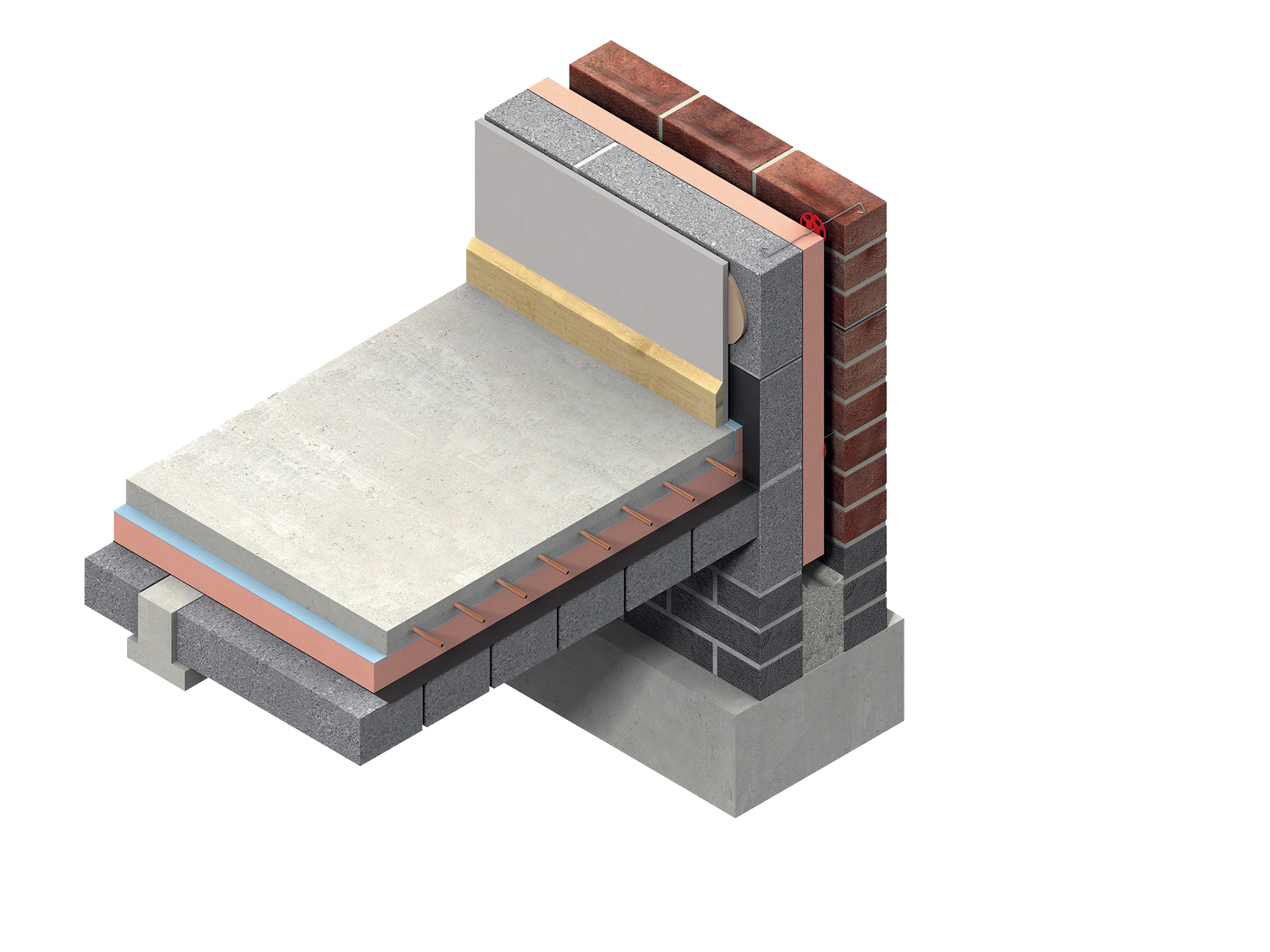

This diagram by Kingspan shows how high-quality insulation can be combined with beam and block floors in a screeded setup to maximise the efficiency of underfloor heating

Source it: Browse more insulation options from Kingspan

The beams are laid at suitable centres to allow them to be filled with standard-sized lightweight aircrete or dense aggregate blocks, until the whole slab area is covered. The floor structure is then brushed over with a 4:1 dry mix of sharp sand and cement to fill the gaps. Because this is an entirely dry process, in that no mortar or adhesive is required, as soon as the slab is laid, it forms a instant working platform, ready for your follow-on trades.

The post The Benefits of Block and Beam Flooring appeared first on Build It.

Article reference The Benefits of Block and Beam Flooring

No comments:

Post a Comment